Chemical milling is a versatile manufacturing process that has become an essential tool for various industries. This process involves the selective removal of material from a workpiece using chemical solutions, allowing for the creation of precise and intricate parts and components. The ability to achieve complex geometries, tight tolerances, and superior surface finishes make chemical milling a valuable asset in a wide range of applications.

In this article, we will explore the top industries in Portland, Oregon, that rely on chemical milling for their success. We will also delve into the importance of this process and the benefits of outsourcing chemical milling services to an experienced chemical milling company in Portland, Oregon.

Overview of the Chemical Milling Process

The chemical milling process begins with the creation of a mask or pattern that covers the areas of the workpiece that are to be protected from the chemical etchant. The exposed areas are then subjected to the chemical solution, which selectively dissolves the material, creating the desired shape or feature. This process allows for the production of parts with complex geometries, tight tolerances, and exceptional surface finishes, making it a preferred choice for many industries.

The chemical milling process is highly versatile and can be used on a wide range of materials, including metals, ceramics, and composites. The specific etchant and process parameters are tailored to the material and the desired outcome, ensuring optimal results.

Importance of Chemical Milling in Various Industries

Chemical milling has become an indispensable tool for many industries, as it allows for the creation of precise and intricate parts that are essential for their success. From aerospace and defense to medical and electronics, chemical milling plays a crucial role in the manufacturing of a wide range of products.

Some of the key industries that rely on chemical milling include:

Aerospace and Defense:

- Production of aircraft and spacecraft components

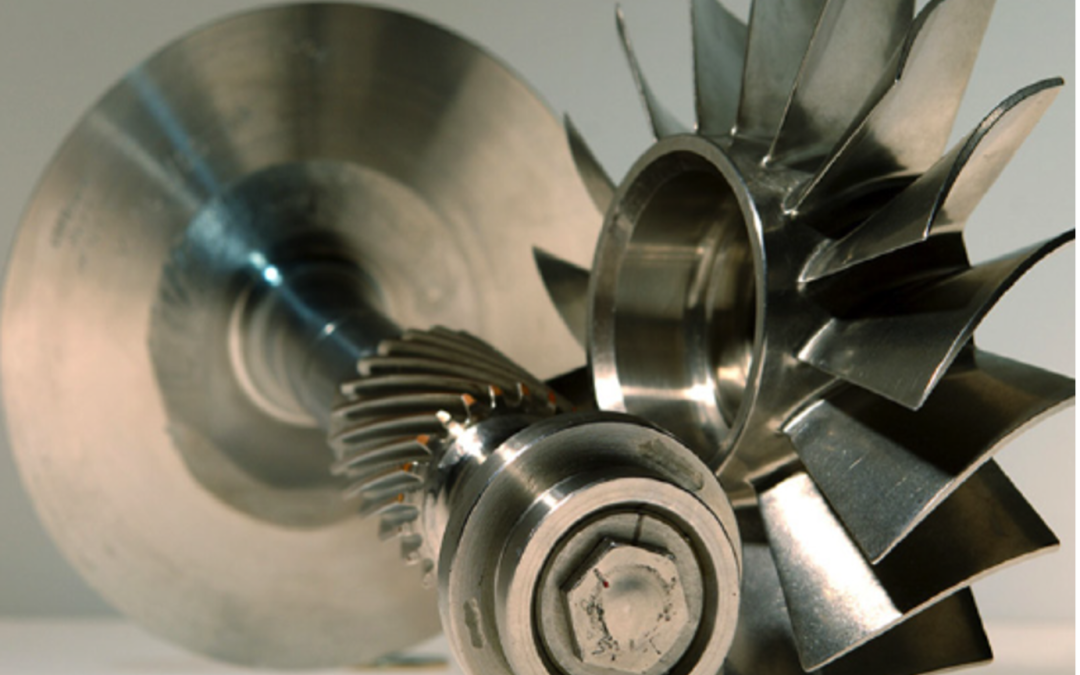

- Fabrication of intricate engine parts and turbine blades

- Manufacture of satellite and missile components

Medical:

- Fabrication of surgical instruments and implants

- Production of medical devices and prosthetics

- Creation of microfluidic devices and lab-on-a-chip technologies

Electronics:

- Manufacture of printed circuit boards and interconnects

- Production of microelectronic components and sensors

- Fabrication of heat sinks and other thermal management solutions

Automotive:

- Production of lightweight and high-performance components

- Fabrication of intricate engine and transmission parts

- Manufacture of specialized automotive sensors and controls

Industrial:

- Production of specialized tools and dies

- Fabrication of custom-made parts for industrial equipment

- Creation of intricate components for various manufacturing processes

The ability to achieve precise and complex geometries, as well as the superior surface finishes, make chemical milling an essential manufacturing process for these industries, allowing them to maintain a competitive edge in the market.

Benefits of Outsourcing Chemical Milling Services in Portland

Outsourcing chemical milling services in Portland can provide a range of benefits for businesses operating in the region. By partnering with a specialized chemical milling company, you can leverage their expertise, equipment, and resources to improve your manufacturing processes and stay competitive in the market.

Here are some of the key benefits of outsourcing chemical milling services in Portland:

- Access to Specialized Expertise: Chemical milling is a highly technical process that requires specialized knowledge and expertise. By outsourcing to a dedicated chemical milling company, you can tap into a team of experts who are well-versed in the latest techniques and technologies, ensuring optimal results for your parts and components.

- Improved Efficiency and Productivity: Outsourcing your chemical milling needs allows you to focus on your core business activities, while the service provider handles the manufacturing process. This can lead to increased efficiency, reduced lead times, and improved overall productivity, as you’ll no longer have to manage the chemical milling process in-house.

- Cost Savings: Maintaining the necessary equipment, facilities, and personnel to perform chemical milling in-house can be costly. By outsourcing, you can benefit from the economies of scale and specialized resources of a dedicated service provider, often resulting in significant cost savings.

- Increased Flexibility: Outsourcing chemical milling services provides you with greater flexibility to scale your operations up or down as needed, without the burden of investing in additional equipment or personnel.

- Enhanced Quality and Consistency: Reputable chemical milling service providers in Portland have the necessary quality control measures and processes in place to ensure consistent, high-quality results for your parts and components.

- Access to the Latest Technologies: Chemical milling companies in Portland, Oregon often invest in the latest equipment and technologies, allowing you to take advantage of these advancements without the need for significant capital investments.

By working with a chemical milling company in Portland, Oregon, you can streamline your manufacturing processes, improve your competitive position, and focus on your core business strengths.

Do You Need a Chemical Milling Company in Portland, Oregon?

If you’re looking for a chemical milling company in Portland, Oregon, that can provide high-quality, precision-engineered parts and components, contact us today.

Our team of experts has the expertise and resources to deliver the results you need to succeed in your industry. Contact us today at 1-888-647-8772 to get started.