Titanium is an exceptional metal that offers several unique characteristics. It’s as strong as steel but 45% lighter, and twice as strong as aluminum but only 60% heavier. The metal is commonly used today in aerospace, chemical processing, medical, and marine applications.

When it comes to titanium, not everyone is familiar with the basics — and that’s where we can help. Below, this titanium plate[SS1] supplier in Los Angeles, California is going to discuss some of the key points that manufacturers should know about the metal and how it is used today.

Titanium: A Quick Overview

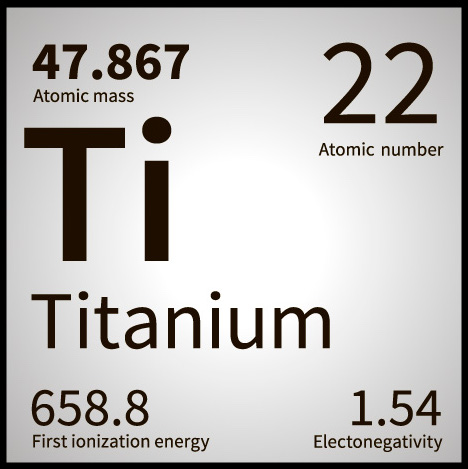

Titanium is a chemical element with the symbol Ti and atomic number 22. The element occurs within a number of mineral deposits, principally rutile and ilmenite, which are widely distributed in the Earth’s crust. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. Then the processing of titanium metal occurs in four major steps: reduction of titanium ore into “sponge”, a porous form; melting of sponge, or sponge plus a master alloy to form an ingot; primary fabrication, where an ingot is converted into general mill products such as billet, bar, plate, sheet, strip, and tube; and secondary fabrication of finished shapes from mill products.

The metal has good ductility, minimum thermal conductivity, low density, and a relatively high melting point. It is physiologically inert, corrosion-resistant, heat-resistant, and has excellent oxidation capabilities. Commercially Pure (C.P.) titanium is 99.2% pure and delivers outstanding corrosion resistance with a superior strength-to-weight ratio. It can even resist acids like hydrochloric acid, chloride solutions, and most organic acids.

When exposed to air, titanium creates a passive oxide coating on itself, which reaches 25 nm thick over time, behaving as a protective layer allowing the metal to perform well even with water or oxygen exposure. Titanium has a relatively high melting point (1,668 °C or 3,034 °F). Plus, its thermodynamic properties prevent the metal from melting in normal conditions, which is very much possible under chemically inert atmospheres. That is why titanium plate suppliers in Los Angeles, California recommend this material for use in harsh environments.

Grades of Titanium?

The ASTM International recognizes 31 grades of titanium metal and alloys, of which grades one through four are commercially pure (unalloyed). Those four vary in tensile strength as a function of oxygen content, with grade 1 being the most ductile (lowest tensile strength with an oxygen content of 0.18%), and grade 4 the least ductile (highest tensile strength with an oxygen content of 0.40%). The remaining grades are alloys, each designed for specific properties of ductility, strength, hardness, electrical resistivity, creep resistance, specific corrosion resistance, and combinations thereof.

How is Titanium Used?

Titanium is most suitable for applications that require lightweight, yet durable materials. Titanium plates, in particular, are preferred in military and commercial aircraft and they are a desirable metal for many high-performing applications.

Titanium plates are available from professional titanium plate suppliers in Los Angeles, California. Their most popular applications include aerospace components, architecture, marine applications, medical implants, sporting equipment, and more.

Why Is Titanium a Popular Material?

Although titanium has a higher cost per pound than steels, its unique characteristics — such as its higher strength and non-magnetic properties — make titanium worth the price for certain applications. Moreover, you can feel confident that you are investing in a dependable product. But make sure you are also engaging with a knowledgeable and reputable titanium plate supplier in Los Angeles, California to get the best possible deal and material.

The characteristics mentioned above give titanium a longer working life, even under challenging conditions. This makes titanium products a top choice among many industry manufacturers.

Looking For a Titanium Plate Supplier in Los Angeles, California?

Are you interested in purchasing titanium for manufacturing purposes? If so, and if you are looking for a premier titanium plate supplier in Los Angeles, California, look no further than the team at Supra Alloys.

In addition to plates, we can supply a wide range of customized titanium products, including bars, coil, rods, sheet, strip, and wire to help meet the needs of your business.

Contact us today at 1-888-647-8772 to discuss your project or send us a form through our website to request a free quote.