Modern aircraft design is dependent on innovative materials that offer exceptional performance, durability, and efficiency. Titanium, a lightweight yet incredibly strong metal, is at the forefront of this revolution.

Below, this aerospace metal supplier in Seattle, Washington is going to highlight the transformative role of titanium in aerospace applications, explaining how it supports advancements in modern aircraft design.

Why Titanium Is Vital for Aircraft Manufacturing

Titanium stands out as a preferred material for aerospace engineering due to its unique properties:

- Strength-to-Weight Ratio: Titanium is as strong as steel but significantly lighter, making it ideal for reducing aircraft weight without compromising structural integrity.

- Corrosion Resistance: Its natural resistance to oxidation and corrosion ensures durability in challenging environments, including high-altitude and marine conditions.

- Heat Resistance: Titanium maintains its properties at elevated temperatures, making it suitable for components exposed to extreme heat, such as jet engines.

These attributes make titanium an indispensable resource for the aerospace industry, especially in Seattle, a hub for aviation innovation.

Titanium in Modern Aircraft Design

The versatility of titanium allows it to be used across multiple components of aircraft, from structural elements to performance-critical parts. Key applications include:

- Fuselage Panels: Titanium is used in sections of the fuselage to enhance durability and reduce weight, contributing to improved fuel efficiency.

- Landing Gear Assemblies: Titanium alloys provide the strength needed to withstand the heavy loads and stresses associated with takeoff and landing.

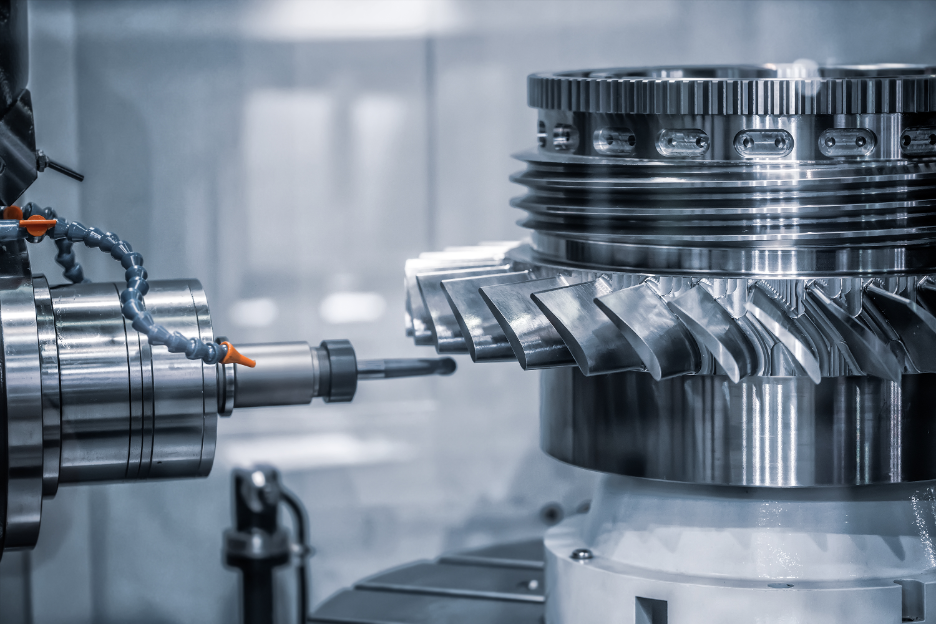

- Jet Engine Components: Titanium is used in engine parts such as compressor blades, casings, and fan disks, where its heat resistance ensures reliable performance under extreme conditions.

- Fasteners and Joints: The lightweight and corrosion-resistant properties of titanium fasteners make them ideal for securing various components while minimizing weight.

A reputable aerospace metal supplier in Seattle, Washington will ensure these applications are supported with precision-engineered titanium materials that meet strict aerospace standards.

Advancing Sustainability in Aviation with Titanium

The aviation industry is increasingly focused on sustainability, and titanium plays a vital role in this transformation. Key contributions include:

- Fuel Efficiency: By reducing aircraft weight, titanium helps improve fuel economy, lowering emissions and operational costs.

- Extended Lifespan: Titanium’s corrosion resistance reduces the need for frequent maintenance and part replacements, minimizing waste and resource consumption.

- Recyclability: Titanium can be recycled without losing its quality, making it a sustainable choice for environmentally conscious manufacturers.

As Seattle’s aviation sector embraces green technologies, titanium supplied by local experts supports these sustainability efforts.

Titanium in Emerging Aerospace Technologies

As the aerospace industry evolves, titanium continues to enable groundbreaking innovations in aircraft design. Key areas include:

- Electric and Hybrid Aircraft: Titanium is a critical material for lightweight components in electric and hybrid aircraft, which prioritize efficiency and sustainability.

- Urban Air Mobility (UAM): With the rise of UAM vehicles, such as air taxis and drones, titanium’s strength and lightweight properties ensure the reliability and performance of these compact aircraft.

- Supersonic and Hypersonic Travel: Titanium’s ability to withstand high temperatures and stress makes it indispensable for supersonic and hypersonic aircraft, where materials must perform under extreme conditions.

The Importance of Partnering with a Reliable Aerospace Metal Supplier

Working with a trusted supplier ensures access to the materials and expertise necessary for aerospace success. Key advantages include:

- Quality Assurance: A reputable supplier provides titanium that meets stringent aerospace standards, ensuring safety and performance.

- Tailored Solutions: Local suppliers can customize titanium materials to meet specific project requirements, from alloy selection to precision dimensions.

- Efficient Delivery: Proximity to aerospace hubs in Seattle allows for faster delivery times, reducing production delays and improving overall efficiency.

By partnering with a trusted aerospace metal supplier in Seattle, Washington, manufacturers can streamline their supply chain and focus on innovation.

Seattle: A Hub for Aerospace Excellence

Seattle is synonymous with aerospace innovation, home to leading manufacturers and a thriving ecosystem of suppliers and engineers. The city’s role in shaping the future of aviation is supported by access to high-quality materials like titanium, provided by local suppliers. From commercial aircraft to emerging technologies, Seattle remains a global leader in aerospace excellence.

Looking for an Aerospace Metal Supplier in Seattle, Washington?

Titanium is revolutionizing modern aircraft design, offering unmatched performance for lightweight, durable, and efficient components. By partnering with the right aerospace metal supplier in Seattle, Washington— such as Supra Alloys — you can take advantage of the highest-quality titanium products that are tailored to meet the demands of today’s aerospace industry. Contact us today at 1-888-647-8772 to learn how we can help.