Titanium, or Ti, is a remarkable metal that has gained immense popularity in the metal industry. Its unique combination of properties and characteristics has made it a highly sought-after material for a wide range of applications. From the aerospace and automotive industries to medical and jewelry sectors, titanium has found its way into numerous fields, revolutionizing the way we think about metals.

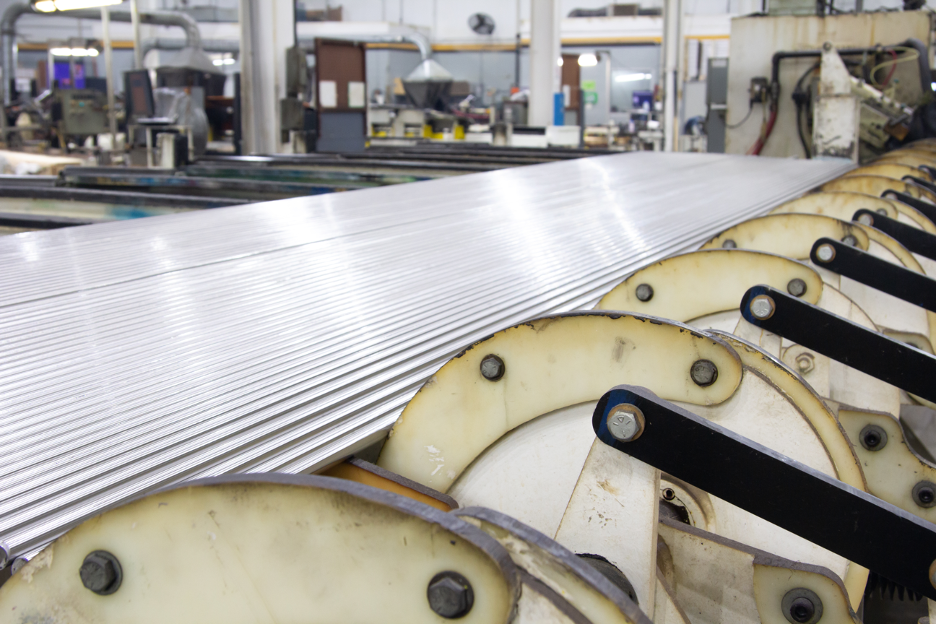

Below, this centerless bar grinding company in Los Angeles, California is going to explore some of the top reasons behind titanium’s rise in the metal industry, discussing its properties, applications, and more.

The properties of titanium that make it popular in the metal industry

One of the key reasons behind titanium’s popularity in the metal industry is its exceptional strength-to-weight ratio. Titanium is incredibly lightweight, weighing about half as much as steel while still maintaining remarkable strength. This makes it an ideal choice for industries where weight reduction is crucial, such as aerospace and automotive. The use of titanium in these sectors has allowed for the development of more fuel-efficient vehicles and aircraft, ultimately leading to reduced carbon emissions and a more sustainable future.

In addition to its strength-to-weight ratio, titanium also boasts excellent corrosion resistance. Unlike many other metals, titanium is highly resistant to corrosion, even in harsh environments. This quality makes it an invaluable material for applications in marine environments, chemical processing plants, and medical implants. By using titanium, manufacturers can ensure the longevity and durability of their products, reducing the need for frequent repairs or replacements.

Furthermore, titanium exhibits remarkable biocompatibility, meaning it is compatible with living tissue. As such, many medical manufacturers rely on centerless bar grinding companies in Los Angeles, California for the materials they need to create medical implants, dental implants, and more. Titanium’s biocompatibility has been shown to reduce the risk of rejection or adverse reactions within the body, which helps ensure a successful integration and long-term functionality of the implants. As medical technology continues to advance, the demand for titanium in the healthcare industry is expected to grow exponentially.

Applications of titanium in various industries

Due to its exceptional properties, titanium finds applications in a wide range of industries. In the aerospace industry, titanium is utilized in the construction of aircraft frames, engines, and landing gears. Its lightweight nature allows for increased fuel efficiency, leading to reduced operational costs and lower carbon emissions. Titanium is also extensively used in the automotive industry, where it is employed in the manufacturing of engine components, exhaust systems, and suspension springs. The use of titanium in automobiles not only improves performance, but it also contributes to weight reduction and enhanced fuel economy.

As mentioned above, the medical sector also relies heavily on titanium. Its biocompatibility, corrosion resistance, and strength make it an ideal material for various medical implants, including artificial joints, dental implants, and bone plates. The use of titanium in medical devices ensures a high level of patient safety and overall success of the procedures. Additionally, titanium is commonly used in the production of surgical instruments, as it can withstand repeated sterilization without compromising its structural integrity.

Beyond aerospace and medical fields, titanium has found applications in the sports industry as well. Centerless bar grinding companies in Los Angeles, California often provide the materials needed to create bicycle frames, golf clubs, tennis rackets, and much more. The lightweight nature of titanium allows athletes to achieve greater speed and maneuverability without sacrificing strength. This has ultimately led to the development of high-performance sports equipment that enhances athletes’ abilities and provides a competitive edge.

Looking for a Centerless Bar Grinding Company in Los Angeles, California?

Are you searching for a reliable centerless bar grinding company in Los Angeles, California that can supply your business with high-quality titanium? If so, look no further than our team at Supra Alloys. With decades of experience in the metal industry, we can provide top-quality titanium products that exceed your exact specifications. Contact us today at 1-888-647-8772 to learn more.