High-temperature alloys play a crucial role in various industries, where they are specially designed for use in extreme temperature conditions. These alloys are desired for their ability to maintain their strength and durability even in environments with elevated temperatures.

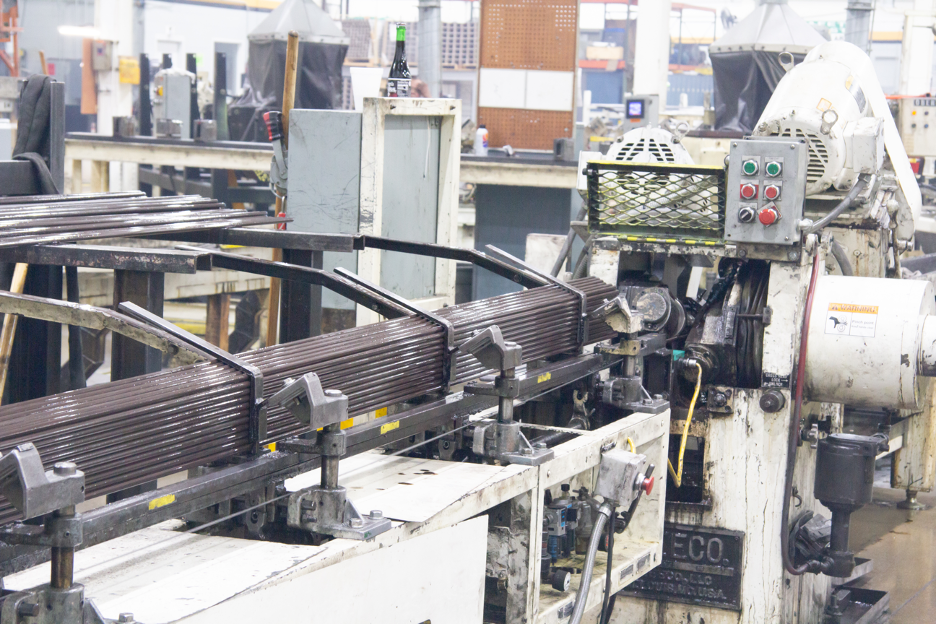

Below, Supra Alloys, a centerless titanium bar grinding company in Dallas, Texas is going to explore some of the key points manufacturers should know about high-temperature alloys, discussing their applications, properties, characteristics, and diverse range of applications.

What Are High-Temperature Alloys?

High-temperature alloys are typically composed of a combination of metals such as nickel, cobalt, and iron, along with other elements like chromium, aluminum, and titanium.

These alloys exhibit exceptional resistance to oxidation and corrosion, making them ideal for use in environments with extreme heat and pressure. Moreover, when produced by a reputable centerless bar grinding company like Supra Alloys, high-temperature alloys possess excellent mechanical properties — including high strength, good ductility, and superior fatigue resistance.

Properties and Characteristics of High-Temperature Alloys

One of the key properties of high-temperature alloys is their ability to withstand elevated temperatures without significant degradation. These alloys retain their strength and structural integrity at temperatures ranging from 500°C to over 1000°C, making them suitable for applications in industries such as aerospace, automotive, energy, and more.

Additionally, high-temperature alloys exhibit excellent thermal stability, ensuring minimal dimensional changes even under extreme heat conditions.

Another important characteristic of high-temperature alloys is their resistance to oxidation and corrosion. When exposed to high temperatures, these alloys form a protective oxide layer on their surface, which acts as a barrier against further oxidation and corrosion. This property is particularly beneficial in industries where components are subjected to intense heat and aggressive chemical environments, such as gas turbines and chemical processing plants.

Furthermore, high-temperature alloys demonstrate remarkable creep resistance, which is the ability to resist deformation under prolonged exposure to high temperatures and mechanical stress.

This property is critical in applications where components are subjected to constant load and high temperatures for extended periods, such as in jet engines and power generation turbines. The combination of high strength, oxidation resistance, and creep resistance makes high- temperature alloys a reliable choice for demanding industrial applications.

Applications of High-Temperature Alloys in the Aerospace Industry

The aerospace industry heavily relies on high-temperature alloys due to the extreme conditions faced by aircraft components. High-temperature alloys are used in the manufacturing of jet engine turbines, where they endure temperatures exceeding 1000°C and high rotational speeds.

These alloys provide excellent creep resistance, ensuring the longevity and reliability of turbine blades. Additionally, high-temperature alloys are utilized in the construction of aircraft exhaust systems, which are exposed to high temperatures and corrosive gases. The superior oxidation resistance of these alloys ensures the durability and performance of these critical components.

Apart from turbine blades and exhaust systems, high-temperature alloys find application in various other aerospace components. For instance, they are used in the fabrication of combustion chambers, which are subjected to extreme temperatures and require high strength and resistance to thermal fatigue.

Centerless bar grinding companies in Dallas, Texas also use high-temperature alloys to manufacture aerospace fasteners, where their high-temperature stability and corrosion resistance are essential for maintaining the structural integrity of aircraft.

Applications of High-Temperature Alloys in the Automotive Industry

In the automotive industry, high-temperature alloys are utilized in a range of applications that require resistance to extreme heat and mechanical stress.

The high-temperature alloys are used in the manufacturing of exhaust systems, the production of turbochargers, and the fabrication of engine components such as valves, pistons, and cylinder heads.

High-temperature alloys offer the required strength, thermal stability, and resistance to oxidation, ensuring the longevity and efficiency of automotive engines. As the automotive industry continues to advance and demand higher performance, high-temperature alloys will play an increasingly vital role in enabling the development of more efficient and durable vehicles.

Applications of High-Temperature Alloys in the Energy Sector

The energy sector heavily relies on high-temperature alloys for various applications, particularly in power generation. High-temperature alloys are utilized in the construction of gas turbines, which are central to electricity generation in gas-fired power plants.

These alloys are employed in the manufacturing of turbine blades, rotors, and casings, where they withstand extreme temperatures and mechanical stress. The excellent creep resistance and thermal stability of high-temperature alloys ensure the efficient and reliable operation of gas turbines, contributing to the overall efficiency of power plants.

High-temperature alloys also find application in nuclear power plants, where they are used in the fabrication of fuel rods and reactor components. These alloys exhibit exceptional resistance to corrosion and radiation damage, making them suitable for use in the harsh environments of nuclear reactors.

Additionally, high-temperature alloys are employed in the production of heat exchangers and boilers in various types of power plants, including coal-fired and biomass plants. The superior thermal stability and resistance to oxidation of these alloys enable efficient heat transfer and ensure the durability of critical components in power generation systems.

Looking for a Centerless Titanium Bar Grinding Company in Dallas, Texas?

Are you searching for a centerless titanium bar grinding company in Dallas, Texas that can produce the high-temperature alloys your business needs? If so, you’ve come to the right place — Supra Alloys has what it takes to be your go-to partner.

With our expertise in material selection and precision grinding services, we can ensure that your high-temperature alloy components meet the highest standards of quality and performance. Contact us today at 1-888-647-8772 to discuss your next project.