Chemical milling is a versatile manufacturing process that is widely used in various industries for its ability to produce complex shapes and precise dimensions. However, when it comes to chemical milling, many people are unaware of the specific applications it can be useful for. If you are looking for some clarity on the topic, you’ve come to the right place.

Below, this chemical milling company in Dallas, Texas is going to delve into the intricacies of chemical milling, exploring how it works, its applications, and the benefits it offers. Whether you are a professional in the manufacturing industry or simply curious about this unique process, this article will provide you with a comprehensive understanding of the chemical milling process.

First: How Does Chemical Milling Work?

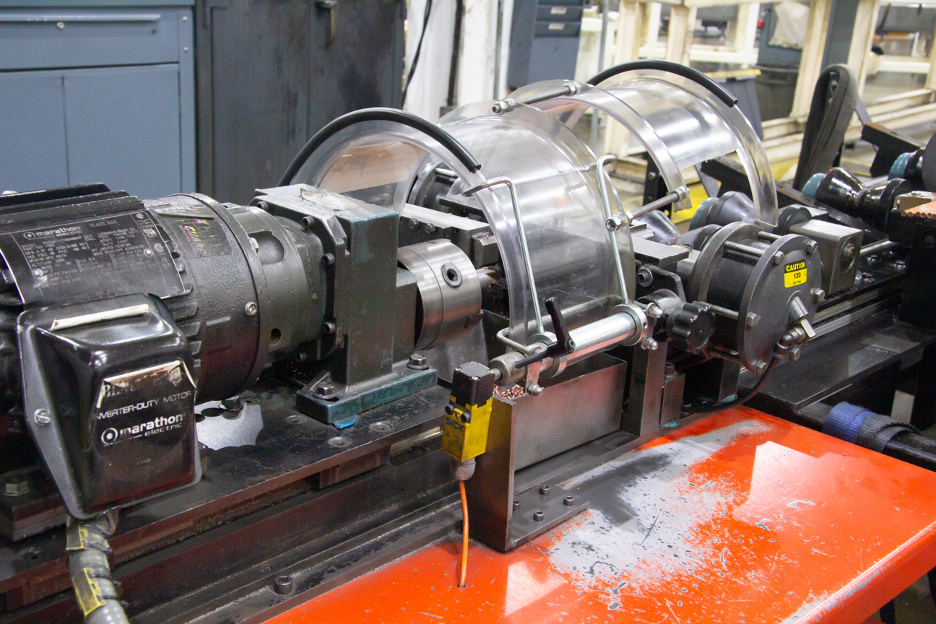

Chemical milling, also known as chemical etching or chemical machining, is a subtractive manufacturing process that involves selectively removing material from a workpiece using a chemical solution. The process begins by applying a resistant mask, such as a polymer film or a photoresist, onto the surface of the workpiece. This mask protects the areas that should not be etched.

Next, the workpiece is immersed in an etchant solution that selectively dissolves the unprotected areas of the material. The etchant solution can be highly corrosive acids or bases, depending on the type of material being etched. As the etchant reacts with the unprotected areas, it gradually removes material, resulting in the desired shape and dimensions.

Chemical milling offers numerous advantages over traditional machining methods. It allows manufacturers to produce complex shapes with high precision and accuracy. Chemical milling companies in Dallas, Texas can use this process to achieve tight tolerances, often within a few micrometers, to ensure the desired specifications are met. Additionally, chemical milling eliminates the need for expensive tooling and reduces the risk of distortion or stress that can occur during mechanical machining.

Applications of Chemical Milling

Chemical milling finds applications in a wide range of industries due to its versatility and precision. One of the key applications of chemical milling is in the aerospace industry. It is used to fabricate complex aerospace components, such as turbine blades and engine parts, with intricate internal features. Chemical milling enables the production of lightweight components with optimal structural integrity, enhancing the performance of aircraft.

In the electronics industry, chemical milling is employed to manufacture printed circuit boards (PCBs). The process allows for precise etching of copper layers to create intricate circuit patterns. Chemical milling ensures the accurate alignment of circuit traces and vias, enabling the fabrication of high-density and high-performance PCBs used in various electronic devices.

The automotive industry also benefits from chemical milling. It is used in the production of automotive parts, such as fuel injector nozzles and transmission components. Chemical milling enables the creation of complex geometries and fine details, contributing to the overall efficiency and performance of vehicles.

The Benefits of Chemical Milling

Chemical milling offers several advantages that make it a preferred manufacturing process in many industries. One of the primary benefits is the ability to produce intricate and complex shapes with high precision. The process allows for the creation of fine details and tight tolerances, ensuring the desired specifications are met consistently.

Another significant benefit is the cost-effectiveness of chemical milling. Compared to traditional machining methods, chemical milling eliminates the need for expensive tooling, reducing production costs. Additionally, the process can be easily scaled up for mass production, making it an efficient choice for high-volume manufacturing.

Chemical milling also offers superior material utilization. Unlike mechanical machining, which generates significant waste as chips or swarf, chemical milling companies in Dallas, Texas utilize a highly efficient process that minimizes material wastage. This makes it an environmentally friendly option, reducing the overall carbon footprint of the manufacturing industry.

Looking for a Chemical Milling Company in Dallas, Texas?

Are you ready to partner with a reliable and experienced chemical milling company in Dallas, Texas that can help you improve your manufacturing processes? If so, Supra Alloys is the top choice. With years of expertise and state-of-the-art facilities, we have what it takes to make sure your products meet the most demanding specifications. Contact us today at 1-888-647-8772 to get started.