Titanium, a remarkable metal known for its strength, durability, and lightweight properties, has been a game-changer in various industries — and particularly in engine innovation. With its exceptional qualities, titanium has revolutionized the way engines are designed and manufactured, leading to enhanced performance and efficiency.

Are you interested in learning how titanium is used today in the production of car engines? If so, you’ve come to the right place. This titanium ground bar supplier in Baltimore, Maryland is going to discuss below.

The History of Titanium in Engine Innovation

The use of titanium in engine building can be traced back to the mid-20th century when its exceptional properties were recognized by engineers and scientists. The aerospace industry was among the first to adopt titanium in engine components due to its high strength, resistance to extreme temperatures, and excellent corrosion resistance.

As engine technology evolved, titanium found its way into automotive engines, contributing to significant advancements in performance and efficiency. In the early days, titanium was primarily used in high-performance racing engines due to its cost and manufacturing challenges. However, with advancements in production techniques and increased availability, titanium became more accessible to mainstream automotive manufacturers.

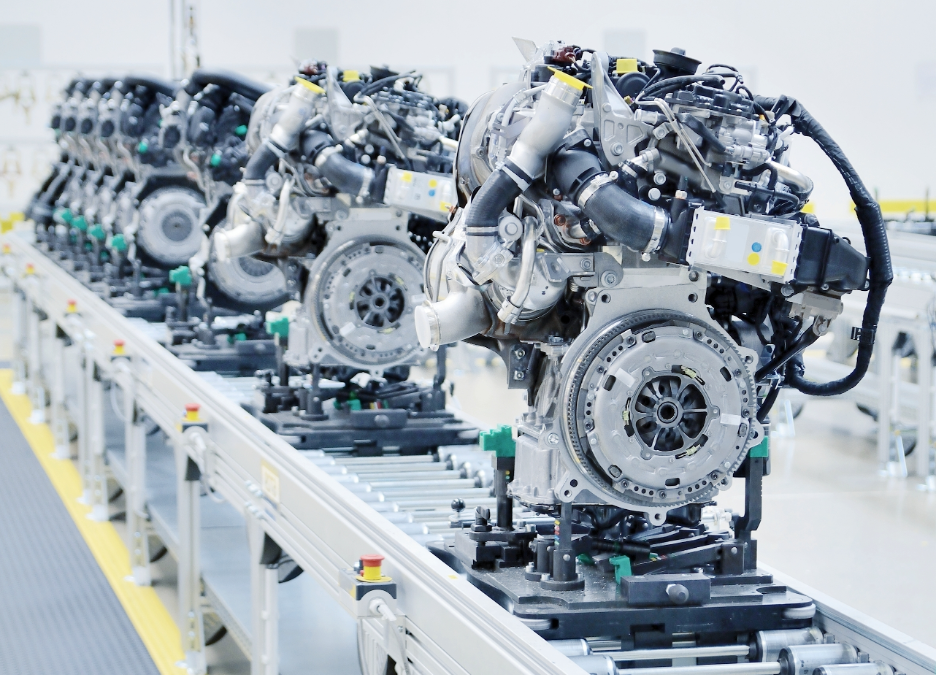

Today, engine manufacturers work with titanium ground bar suppliers in Baltimore, Maryland to produce a wide range of engine components, including valves, connecting rods, pistons, and exhaust systems, to name a few. The lightweight nature of titanium ground bars allows for reduced engine weight, which ultimately results in improved fuel efficiency and overall performance.

The Advantages of Using Titanium in Engines

The use of titanium in engine design brings forth numerous advantages that contribute to superior performance and efficiency. First, titanium’s exceptional strength-to-weight ratio significantly reduces the overall weight of the engine. This weight reduction translates into enhanced fuel efficiency, as the engine does not have to work as hard to propel the vehicle. Additionally, the lightweight nature of titanium allows for better weight distribution, leading to improved handling and maneuverability.

Another significant advantage of titanium is its exceptional resistance to corrosion. Unlike other metals, titanium does not rust or corrode easily, making it an ideal material for engine components that are exposed to high temperatures and harsh environments. This corrosion resistance ensures the longevity and reliability of the engine, reducing maintenance costs and increasing its lifespan.

Furthermore, when processed by a professional titanium ground bar supplier in Baltimore, Maryland, the material exhibits excellent heat resistance. This makes it ideal for components that are subjected to extreme temperatures, such as exhaust systems and turbine blades. Its ability to withstand high temperatures without deforming or losing strength ensures optimal engine performance, even under demanding conditions.

Titanium Alloys and Their Applications in the Automotive Industry

While pure titanium possesses remarkable properties, it is often alloyed with other metals to further enhance its characteristics. Titanium alloys offer a wide range of mechanical properties, allowing engineers to tailor the material to specific application requirements. In the automotive industry, titanium alloys find extensive use in engine components where strength, durability, and heat resistance are crucial.

One of the most popular titanium alloys used in the automotive industry is Ti-6Al-4V, also known as Grade 5 titanium. This alloy combines titanium with aluminum and vanadium, resulting in a material with excellent strength, low density, and exceptional heat resistance. Ti-6Al-4V is commonly utilized in valves, connecting rods, and turbocharger impellers, where its high strength and heat resistance contribute to improved engine performance.

Another notable titanium alloy is Ti-3Al-2.5V, which offers a unique balance between strength, ductility, and formability. This alloy is often used in applications where complex shapes are required, such as exhaust systems and intake manifolds. Its excellent weldability and corrosion resistance make it an attractive choice in the automotive industry.

Sustainability and Environmental Impact of Titanium Usage in Engines

When it comes to sustainability, titanium boasts several advantages compared to traditional metals used in engine manufacturing. First, titanium’s lightweight nature contributes to reduced fuel consumption, resulting in lower carbon emissions. With the increasing focus on environmental sustainability, titanium’s ability to improve fuel efficiency aligns perfectly with the industry’s goals of reducing greenhouse gas emissions.

Additionally, titanium’s exceptional corrosion resistance ensures the longevity of engine components, reducing the need for frequent replacements. This not only saves costs, but also minimizes the environmental impact associated with the disposal and manufacturing of new components. Furthermore, titanium is fully recyclable, making it a sustainable choice for engine manufacturing.

Looking for a Titanium Ground Bar Supplier in Baltimore, Maryland?

Are you searching for top-quality titanium ground bars that can improve your engine performance? Searching for the best titanium ground bar supplier in Baltimore, Maryland? If so, Supra Alloys is the top choice. To explore the myriad of possibilities offered by titanium in engine innovation, contact us today at 1-888-647-8772.