Titanium, a versatile and highly sought-after metal, has found its way into a wide range of industries today due to its exceptional properties. From aerospace and automotive applications to medical devices and construction, titanium offers a combination of strength, durability, and corrosion resistance that is tough to match. Plus, it is very lightweight in nature, making it a highly sought after metal.

When it comes to titanium, however, it’s important to note that the metal is not always created equal. In fact, low-quality titanium can pose serious risks to safety, jeopardizing the integrity of structures, equipment, and even human lives.

Are you interested in learning about the potential risks that are associated with using low-quality titanium? This titanium ground bar supplier in Detroit, Michigan is going to explain below.

The risks of using low-quality titanium

Low-quality titanium can lead to catastrophic consequences, undermining the very purpose for which it is used. Structural failures in buildings, bridges, and aircraft can occur when subpar titanium is employed. The inferior strength and lack of structural integrity can compromise the safety of these structures, putting countless lives at risk.

Furthermore, low-quality titanium may exhibit poor corrosion resistance, leading to premature degradation and failure of components. In medical devices, such as implants or surgical instruments, the use of low-quality titanium can result in complications, infections, and even implant failure.

How to identify low-quality titanium

Identifying low-quality titanium is crucial to ensuring safety and preventing potential disasters. There are several key indicators that can help you determine the quality of titanium:

- Certifications and compliance: Reputable titanium ground bar suppliers in Detroit, Michigan will provide documentation and certifications that guarantee their products meet industry standards and regulations. You’ll want to look for certifications such as ISO 9001 or AS9100, which demonstrate a commitment to quality control and compliance.

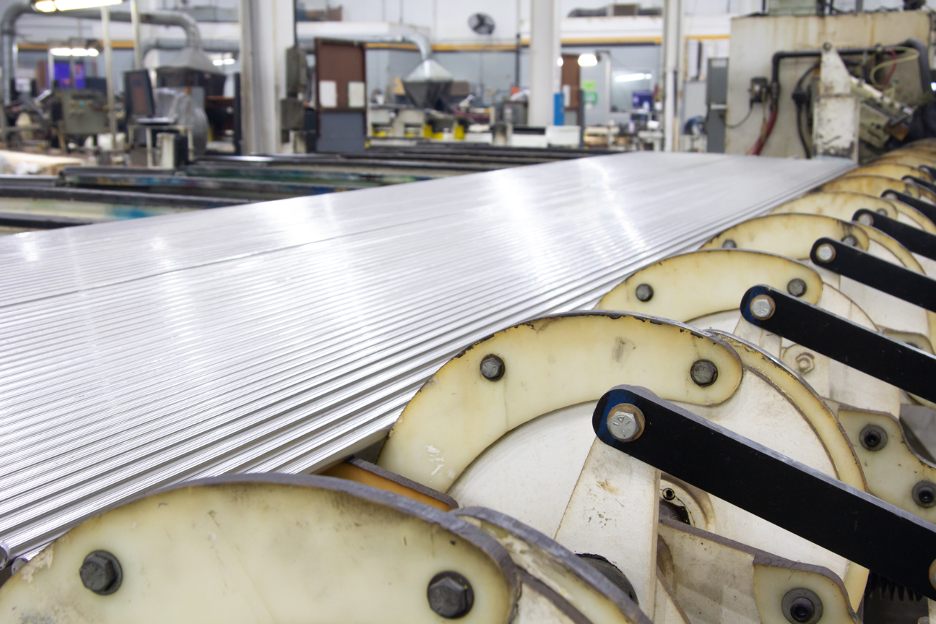

- Visual inspection: It’s important to examine the surface of the titanium for any signs of discoloration, roughness, or inconsistencies. High-quality titanium should have a smooth, uniform appearance.

- Chemical composition: You can request a chemical analysis report to verify the composition of the titanium. Impurities, such as excessive oxygen or iron, can weaken the material and indicate poor quality.

- Mechanical properties: It’s important to determine the mechanical properties of the titanium, such as tensile strength and elongation. These values should align with industry standards and specifications, ensuring the material can withstand the intended application.

Safety risks with low-quality titanium

The use of low-quality titanium can have severe consequences on safety across various industries. In the aerospace sector, where titanium is widely used for aircraft components, the failure of subpar titanium can result in catastrophic accidents. From engine parts to landing gears, the structural integrity of these critical components is extremely important. Any compromise in quality can lead to devastating consequences, endangering the lives of passengers and crew.

In the construction industry, low-quality titanium can undermine the stability of buildings, bridges, and other structures. The metal’s strength and corrosion resistance are essential for ensuring the longevity and safety of these projects. However, when inferior titanium is utilized, the risk of collapse and structural failure increases significantly.

Even in the medical field, where titanium is used extensively for implants and surgical instruments, the impact of low-quality titanium cannot be overlooked. Implant failures, infections, and complications can arise when the material does not meet the necessary standards. Patients’ safety and well-being depend on the use of high-quality titanium that meets stringent requirements.

The role of regulations and standards in ensuring titanium quality

To mitigate the risks associated with low-quality titanium, various regulations and standards play a crucial role. Regulatory bodies and industry organizations set guidelines and specifications that titanium ground bar suppliers in Detroit, Michigan must adhere to. These standards ensure that the titanium used in critical applications meets the necessary quality requirements. Compliance with these regulations helps guarantee the safety and reliability of structures, equipment, and medical devices.

In addition to regulatory standards, industry certifications provide further assurance of titanium quality. Suppliers that hold certifications such as ISO 9001 or AS9100 have undergone rigorous quality management processes and audits. These certifications demonstrate a commitment to consistently delivering high-quality titanium products.

Looking for a Titanium Ground Bar Supplier in Detroit, Michigan?

When safety is paramount, it is essential to partner with a trusted supplier of high-quality titanium. That’s where Supra Alloys can help. As the top-rated titanium ground bar supplier in Detroit, Michigan, we are committed to providing superior titanium products that meet the highest industry standards. With a wide range of titanium alloys and strict quality control measures, we do everything we can to ensure the safety and reliability of our products.

Contact us today at 1-888-647-8772 to learn how we can help with your next project.