Cincinnati, Ohio is home to a wide range of industries, ranging from aerospace and defense to medical devices and chemical processing. These sectors demand high-performance materials that offer strength, corrosion resistance, and weight savings.

That’s where titanium plate comes in. Used across structural, machining, and thermal applications, this material continues to shape the backbone of advanced fabrication in the Midwest. As a result, sourcing from a reliable titanium plate supplier in Cincinnati, Ohio is essential for maintaining material standards, regulatory compliance, and end-use efficiency.

Whether it’s large-format chemical tanks or custom-cut aerospace brackets, titanium plate is a staple in precision manufacturing. Its ability to remain stable under extreme temperatures and resist corrosion makes it one of the most valuable metals in today’s fabrication workflows.

Aerospace and Defense: Lightweight Strength Where It Counts

Titanium’s exceptional strength-to-weight ratio is one of the primary reasons it’s so widely used in the aerospace industry. In Cincinnati, contractors and parts manufacturers working with both commercial and defense aircraft turn to titanium plate for critical structural applications. These may include:

- Bulkheads and fuselage components

- Engine mount brackets

- Wing and landing gear supports

These applications require a consistent, machinable, and certified supply of material. A trusted titanium plate supplier in Cincinnati, Ohio can provide plates in grades such as Grade 2 for general use or Grade 5 (Ti-6Al-4V) for high-strength aerospace work, ensuring the metal can handle dynamic loading, fatigue, and high-altitude exposure.

Medical Manufacturing: Biocompatible and Corrosion-Resistant

Cincinnati is also home to a growing base of medical device manufacturers. From orthopedic equipment to surgical tooling, titanium is prized for its biocompatibility and ability to resist bodily fluids and sterilization agents. Though rod and wire forms are more common for implants, titanium plate plays a key role in:

- Imaging equipment

- Surgical trays and instrument panels

- Laboratory containment chambers

Medical applications often require strict surface quality and chemical consistency. Reputable titanium plate suppliers in Cincinnati, Ohio can help you gain access to traceable, spec-compliant materials that can be used for a wide range of medical applications.

Chemical and Industrial Processing: Built for Harsh Environments

Titanium’s chemical inertness is unmatched among common industrial metals. In chemical plants and manufacturing facilities throughout Cincinnati, titanium plate is often used to line tanks, reinforce pumps, and serve as baffles or plates in heat exchangers. These components are exposed to:

- Acids and caustics

- Steam and high heat

- Pressure cycling and thermal expansion

The durability of titanium under such harsh conditions reduces maintenance, avoids contamination, and extends service life, making it a top choice for process engineers. Experienced titanium plate suppliers often work closely with these clients to ensure the proper plate thickness, grade, and finish is available for each unique application.

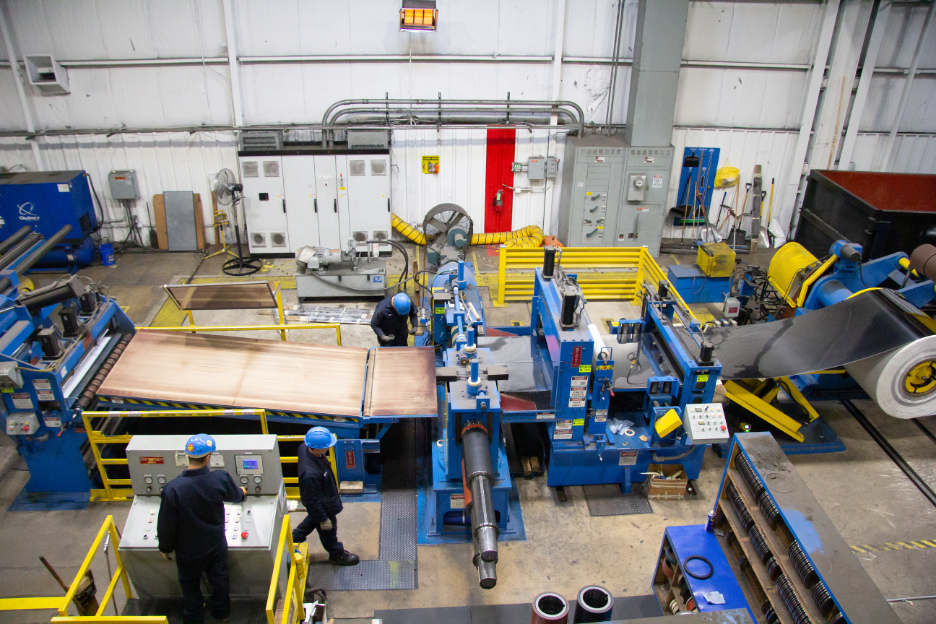

Custom Fabrication: Cutting, Welding, and Precision Fit

In addition to raw strength and resistance, titanium’s versatility is another reason it’s favored in local fabrication shops. Titanium plate can be:

- Waterjet or laser cut into precision parts

- Welded using inert gas processes

- Bent or formed within specific tolerances

Cincinnati’s metal fabricators often produce short-run or custom-fitted assemblies for prototypes, R&D, or machinery repair. Access to locally sourced titanium plate shortens lead times and reduces transportation costs, while ensuring quality and consistency. When working with a local titanium plate supplier, manufacturers can also get help sourcing specific alloys or temper conditions for their fabrication setup.

Sustainability and Titanium Plate Recyclability

Environmental sustainability is increasingly important for manufacturers in Ohio. Fortunately, titanium is not only durable but also highly recyclable. Titanium scrap from plate cutting and fabrication is often reclaimed and reprocessed, reducing waste. This aligns with sustainability goals for aerospace, automotive, and industrial clients alike.

Working with a titanium plate supplier in Cincinnati, Ohio also supports regional supply chains. This helps cut down on emissions from long-haul transportation and promotes circular use of high-value materials.

Looking for a Titanium Plate Supplier in Cincinnati, Ohio?

Titanium plate may be a global material, but access to it should feel local. Cincinnati-based industries can benefit from working with suppliers that understand their application requirements and can deliver technical support, inventory planning, and fast turnarounds.

Are you ready to partner with a professional titanium plate supplier in Cincinnati, Ohio that can help you gain access to the high-quality materials needed for your projects? If so, Supra Alloys is here to help. Whether the project involves aircraft parts, heat exchanger baffles, or custom fabrication, we can ensure reliability without sacrificing on quality. Contact us today at 1-888-647-8772 to get started.